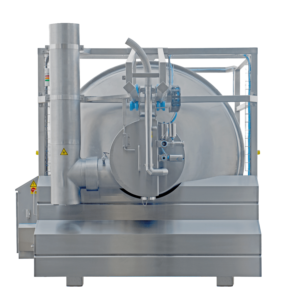

Coating Tumbler

Cryogenic sauce and seasoning coating.

CRYOGENIC COATING

Cryogenic tumblers are used to envelop a substrat with a sauce or another kind of coating. The end-product of the batch process is an IQF (individually quick frozen) added value product.

APPLICATIONS

Manufacturing of convenience food and ready meal components. The substrate can be seafood, vegetables, meat, potatoes, pasta or other free rolling products.

FEATURES AND BENEFITS

Cryogenic coating is fast, flexible and efficient. The process can be fine tuned to prevent breakage and to inhibit the production of fines. Due to special internal parts, the discharging of the tumbler is swift and no segregation occurs (within 36 seconds).

A programmable logical controller, able to memorize several recipes, guides the tumbler through the different sequences of the coating process.

Thanks to specially designed nozzles and injection systems, the amount of coating can be up to 200 % in weight. Tumblers exist in nominal batch sizes of 50 to 800 kg (500 liter to 8800 liter).

Coating tumbler